Our Machineries

PTB 400

A machine used to cut (EPS) polystyrene blocks in sheets, useful for the production of precast sandwich panels. The machine cuts the blocks horizontally and vertically and obtains polystyrene Polistop sheets of different thicknesses and shapes.

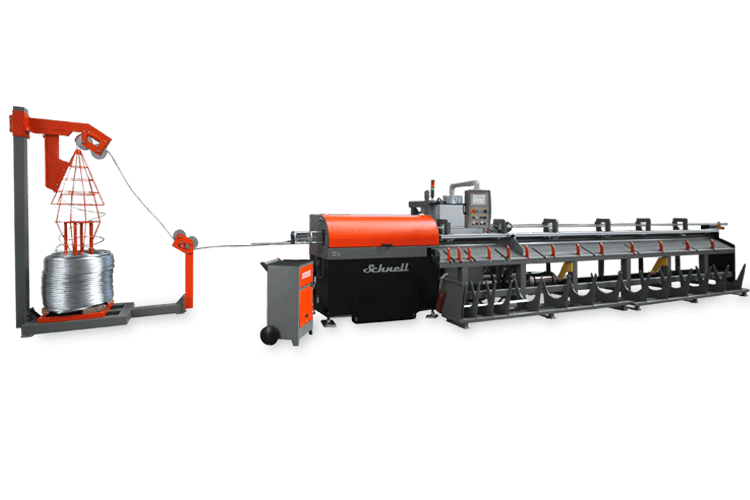

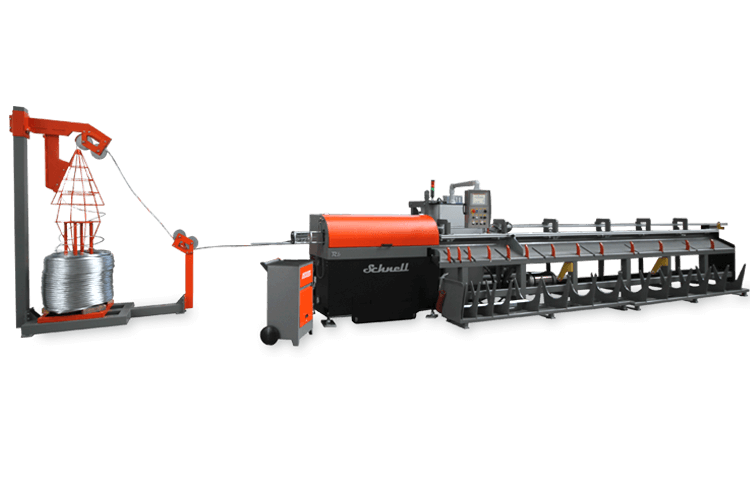

R6

Rotor type wire straightening machine used for the production of cut-to-size wires up to Ø 6 mm (#3).

Driven by digital electric servomotors.

– Max pulling speed: 160 m/ min (525 ft/ min)

– High speed cutting unit with brushless (less than 0.1 sec)

– Web Teleassistance

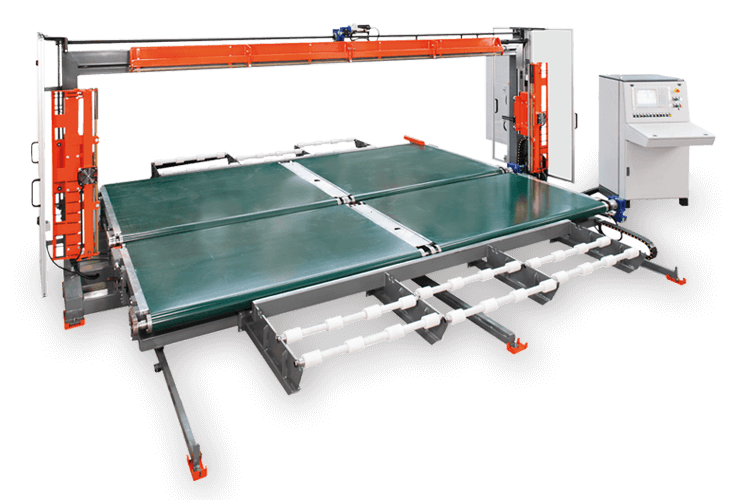

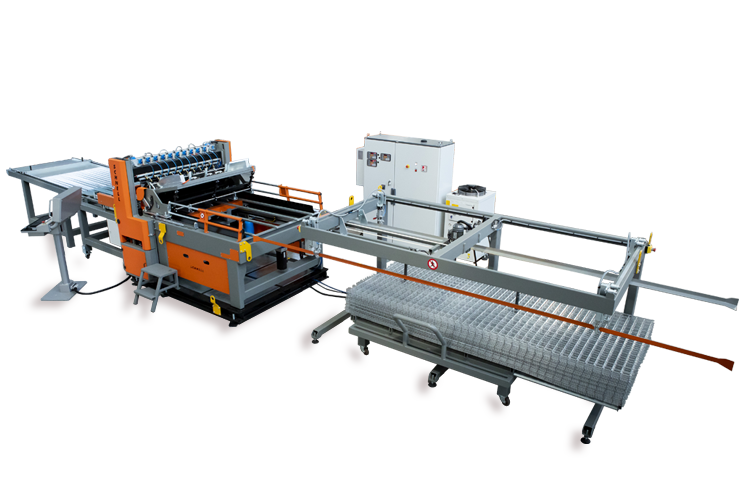

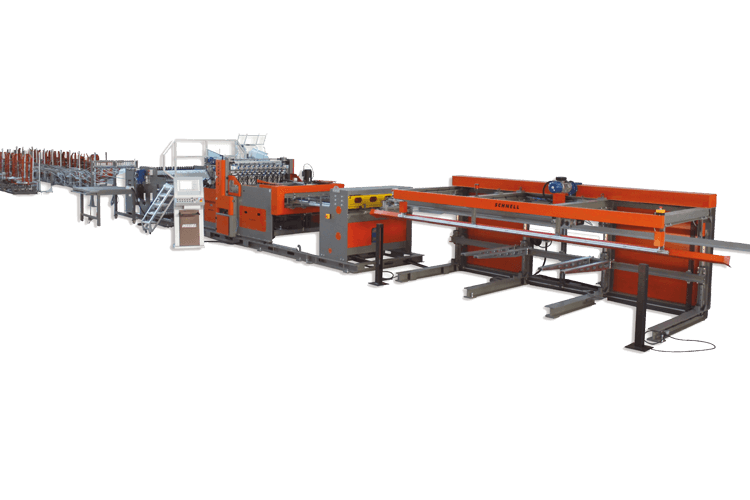

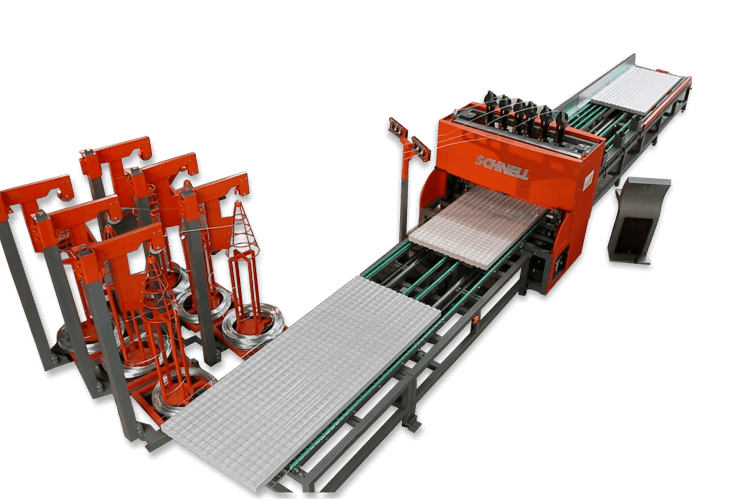

ML 1250 BB

Mesh welding machine used for the production of electro-welded mesh fed by wires. The automatic wire mesh welding machine can manufacture electro-welded mesh from pre-straightened wire, both longitudinal and transversal. The mesh maximum width is equal to 1250 mm, the length is variable between 2000 mm and 6000 mm. These electro-welded mesh are used for the production of prefabricated sandwich panels.

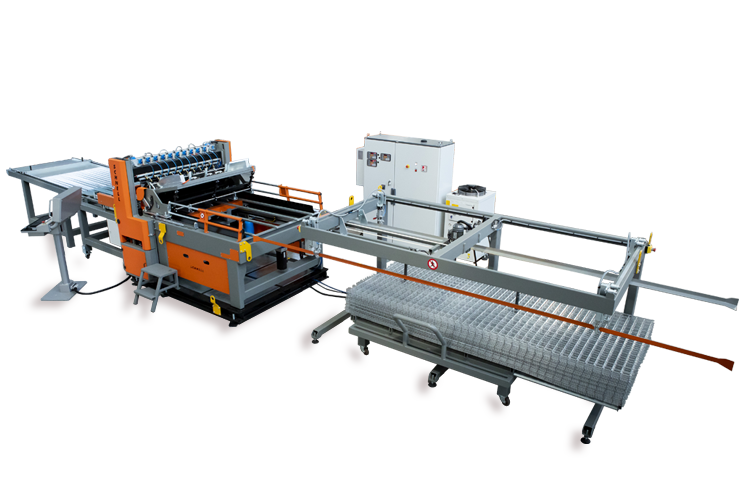

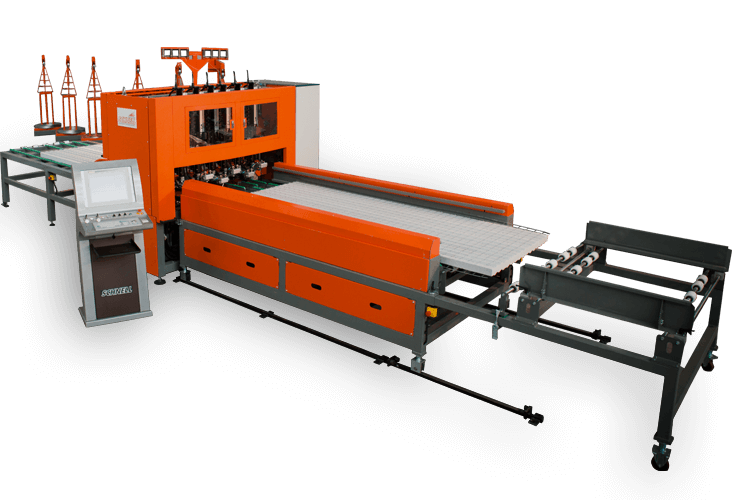

ML 1250 BC

Mesh welding machine used for the production of electro welded meshes supplied by bars and coils. This machine produces electro welded meshes with transversal wires pre-straightened and cut to size and longitudinal wires supplied directly from coils. The mesh maximum width is equal to 1250 mm and the length is unlimited. These electro-welded mesh are used for the production of prefabricated sandwich panels.

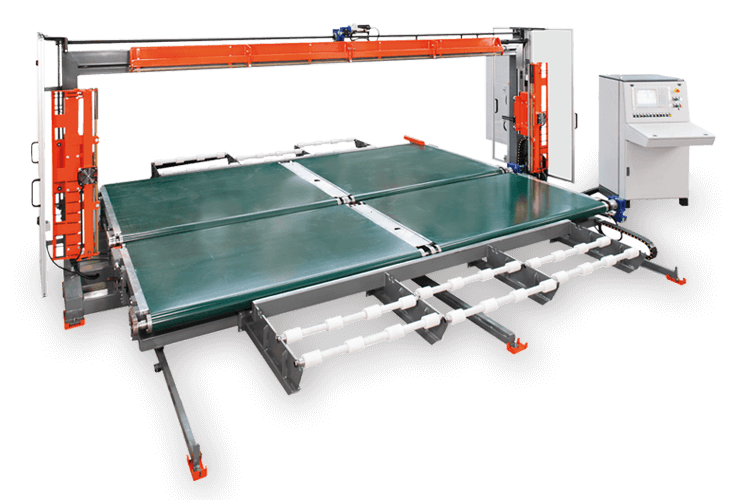

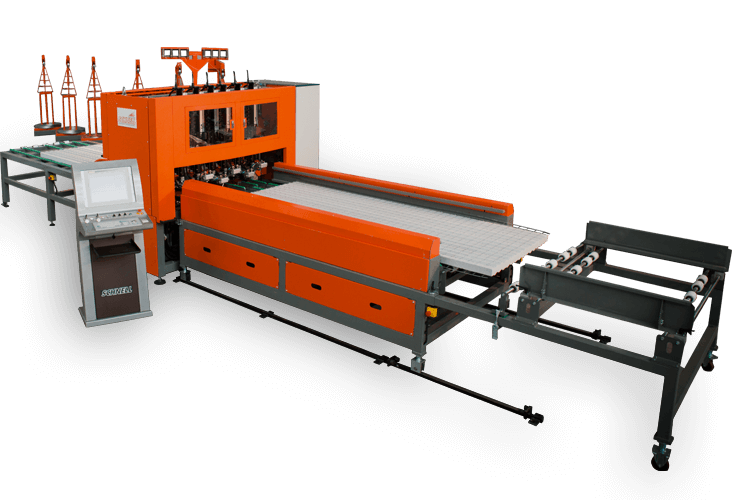

AP 120 M

Mesh welding machine used for the production of electro-welded mesh fed by wires. The automatic wire mesh welding machine can manufacture electro-welded mesh from pre-straightened wire, both longitudinal and transversal. The mesh maximum width is equal to 1250 mm, the length is variable between 2000 mm and 6000 mm.

These electro-welded mesh are used for the production of prefabricated sand

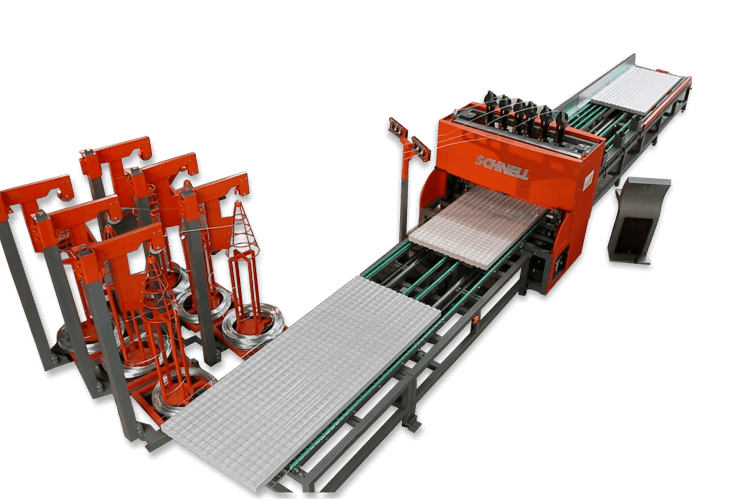

AP 120 CA/E

Completely automatic assembling machine used for the assembling of prefabricated sandwich panels. Once the first mesh, the polystyrene sheet and the second mesh are positioned on the welding bench, the assembling machine puts and welds the vertical connectors to the two external mesh. This way it is possible to produce all types of insulated panels: single panels, double panels and floor panels of different thicknesses, ideal for the construction all type of buildings.

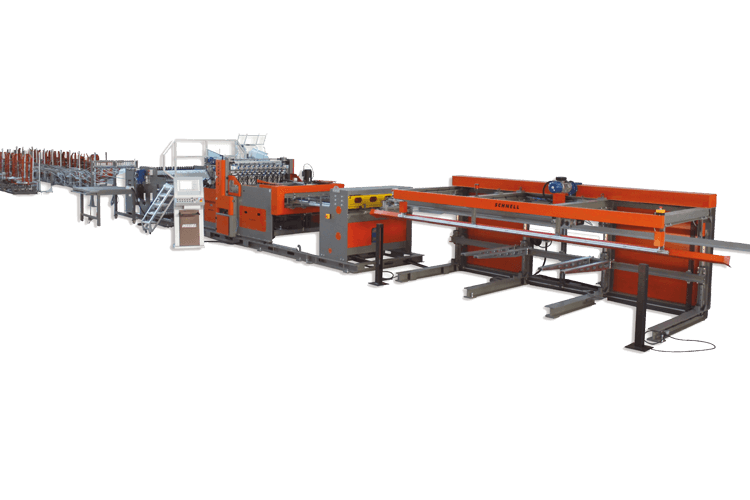

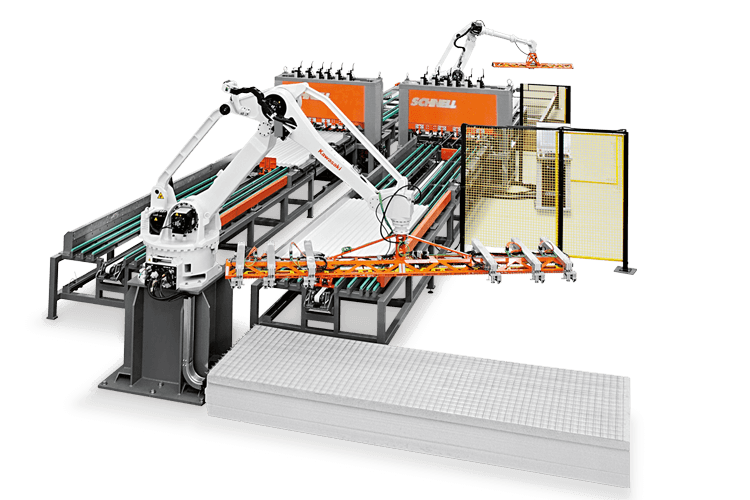

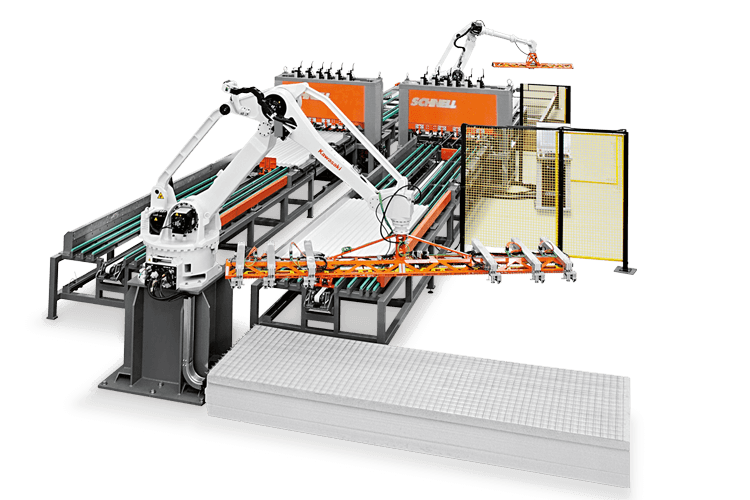

TJI 3200

Robotic plant used for the production of prefabricated sandwich panels made up of one or more assembling machines working side by side fed by a robot that loads the produced mesh and the polystyrene sheets that have already been cut. Once assembled, another robot placed at the end of the machine, unloads, stacks and binds the polystyrene panels to be used as main walls, partitions and infill walls of prefabricated and industrial buildings.

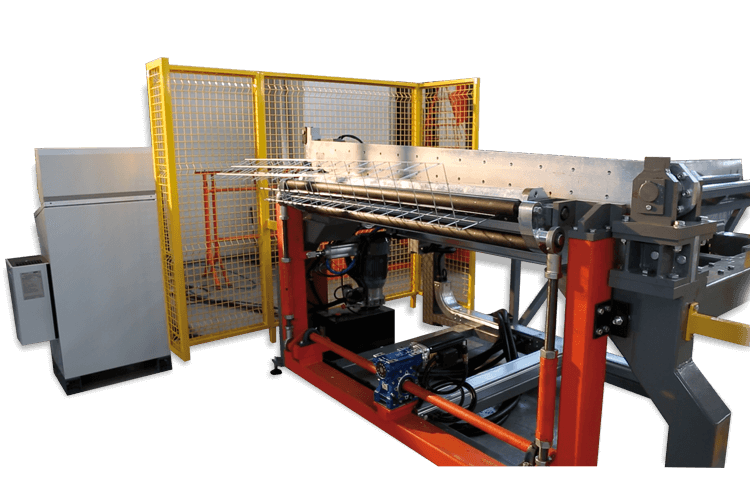

PTRE

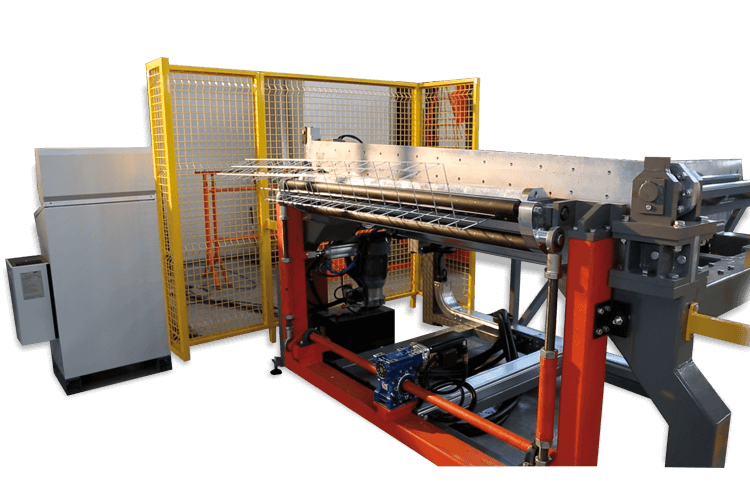

Electromechanical automatic mesh cutting and bending machine used for the production of U, L, Z-shaped mesh and sandwich panels.

Mesh handling is guaranteed by clamps driven by electric servomotors.

– Max mesh width: 1250 mm;

– Max mesh length: 6000 mm.